Sagars Blog

Si buscas

hosting web,

dominios web,

correos empresariales o

crear páginas web gratis,

ingresa a

PaginaMX

Por otro lado, si buscas crear códigos qr online ingresa al Creador de Códigos QR más potente que existe

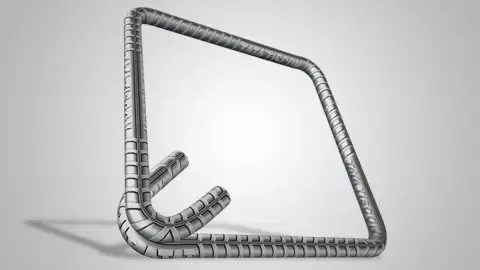

Selecting The Ideal Stirrups For Your Construction Needs

17 Apr 24 - 22:24

Stirrups come in different shapes and sizes and the size of a stirrup depends on the diameter and spacing. The common stirrup sizes include 6mm, 8mm, 10mm and 12mm. The type of stirrup to be used depends on the design of the structure. Stirrups help to fix the bars in the correct position and resist diagonal tension. They can prevent the structure from collapsing.

In small reinforcement concrete structures, the stirrups are used in the columns, beams and footing structures. Making stirrups at the construction site can be time-consuming and can lead to wastage of material. It can be costly too therefore ready-made stirrups are used.

Ready-made stirrups can be used to reduce the labour cost of construction and it also leads to zero wastage of material. The stirrups are made up of high-strength TMT rebars and have a ribbed surface. One of the ready-made stirrups is the Tiscon Superlinks which are manufactured using innovative automation. Strict quality control ensures high quality, accurate dimension and consistency. The stirrups come with a 135-degree hook for better utilization in the structure.

Selecting stirrups

The stirrups are available in different sizes and are used to ensure proper structural integrity and load-bearing capacity. The size and shape of the stirrup should be chosen based on the size of the structure like beams or columns. The stirrup should be bought from a reputable manufacturer.

The stirrups should be packed to allow easy transportation, storage and usage. The packaging will also protect it from environmental damage. The stirrups should be of the industrial standard prescribed by the authorities. It must be of the right weight and size.

The spacing of the stirrup in the main structure should be decided by the designer as this will help select the right stirrups.

Purpose of stirrups

The stirrups are placed at a certain spacing along the length of a main beam of columns. The two types of failures that can occur in the main beam or columns are flexural failure and shear failure. As the load increases the beam or column can sag which results in flexural failure. The stirrups provide resistance due to flexure.

A shear crack may develop at an angle of 45 degrees to the horizontal and grow towards the bottom and the top. Diagonal tension occurs as concrete is stronger in compression than the tension. Shear failure is considered brittle and therefore it should be avoided. Stirrups are used to resist the shear and prevent the main bar from bending outwards.

Stirrups are used to prevent the main beams and columns from buckling. The stirrups can be placed diagonally or vertically. Stirrups are used in places where there are high chances of shearing like bearing points and large loads. Stirrups help to keep the structure straight and provide more strength to it.

Tu Sitio Web Gratis

© 2025 Sagars Blog320666

Steelon Call

06 May 2024 - 05:59 am

Yes stirrup is an important part of combining TMT bars in construction.

Add a comment